What does it take to design and build an industrial processing tower that meets modern production demands? The answer lies in precision engineering, seamless collaboration, and a strong focus on safety and efficiency.

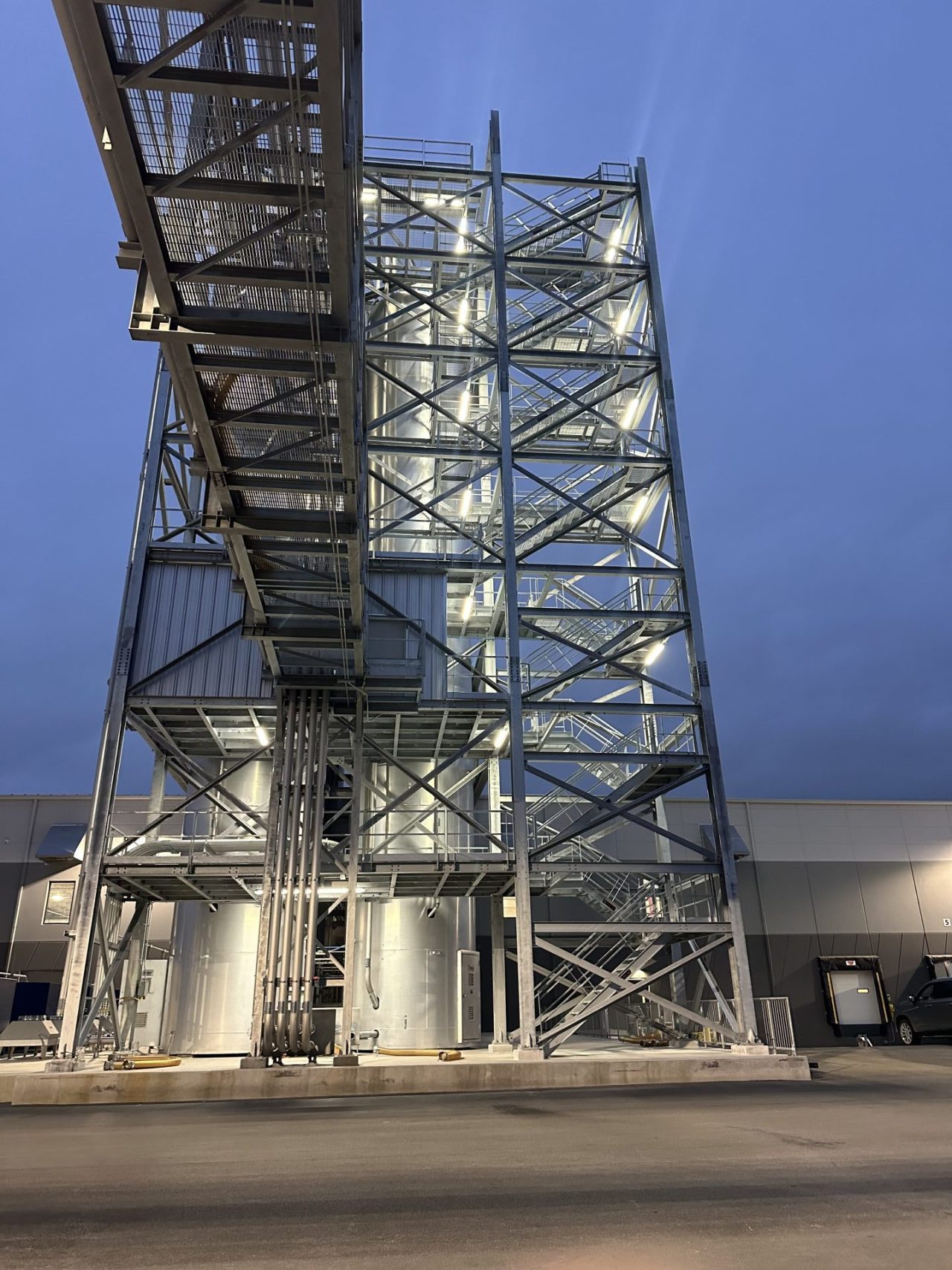

Our latest project in Indianapolis, Indiana, highlights these principles in action – a multi-level processing tower built to support high-capacity material handling and advanced production processes. This project showcases how Hawk EPC’s engineering expertise delivers solutions that meet the demands of today’s industrial facilities.

What Is an Industrial Processing Tower?

An industrial processing tower is a multi-story structure designed to house key process equipment, including stainless steel tanks, piping systems, and conveyors for material movement. These towers are essential in industries such as:

- Food Processing

- Chemical Manufacturing

- Pharmaceutical Production

- Bulk Material Handling

By integrating advanced engineering and durable materials, these towers optimize production workflows while ensuring safety and compliance.

Project Overview: Building a High-Capacity System in Indianapolis

The Indianapolis project involved constructing a steel-frame tower with multiple levels of integrated platforms and stair systems. These features allow operators to safely access critical equipment while maintaining compliance with OSHA safety standards.

Key Components of the Tower:

- Stainless Steel Process Vessels: Designed for storage and mixing, ensuring material integrity.

- Precision Piping Systems: Enable efficient and reliable material transfer.

- Structural Steel Framework: Provides durability and stability for long-term performance.

- Overhead Material Handling Systems: Streamline workflows and improve operational efficiency.

How This Project Improves Efficiency and Safety

Efficiency and safety were top priorities throughout the project. Key design features include:

- Easy-Access Platforms: Simplify maintenance and reduce downtime.

- LED Lighting: Enhances visibility for around-the-clock operations.

- High-Strength Steel Components: Ensure durability in harsh industrial environments.

These elements work together to create a structure that supports 24/7 operations while minimizing maintenance risks and maximizing uptime.

Why Industrial Facilities Need Structures Like This

As industries face increasing performance demands, infrastructure like this processing tower provides critical advantages:

- Optimized Material Flow: Speeds up production processes and reduces bottlenecks.

- Reduced Downtime: Easy maintenance access ensures minimal disruption to operations.

- Long-Term Durability: High-quality materials withstand harsh conditions, ensuring reliability.

FAQs About Industrial Processing Towers

Q: What industries use processing towers?

A: Industries such as food manufacturing, chemical processing, pharmaceutical production, and bulk material handling rely on these towers for efficient operations.

Q: Why is structural steel important for these towers?

A: Structural steel offers superior strength, corrosion resistance, and a long service life, making it ideal for demanding industrial environments.

Q: How long does it take to build an industrial tower like this?

A: Timelines vary based on complexity, but projects typically require several months from design to installation.

Durability and Uptime: Built for Performance

Durability and uptime were key priorities for this project. Each structural component was carefully selected for strength, ease of maintenance, and long-term performance in harsh industrial environments. Features like high-strength materials, LED lighting, and easy-access work areas ensure the tower supports 24/7 operations with minimal downtime.

For industrial operations, infrastructure like this is more than just support – it’s a strategic advantage. As production standards rise, facilities need systems that perform under pressure and scale with demand. This project demonstrates what’s possible when engineering, fabrication, and construction are fully aligned under one roof.

Why Choose Hawk EPC for Industrial Projects?

With all scopes managed in-house, Hawk EPC kept the Indianapolis project on schedule, aligned with performance goals, and built for long-term results. This is another example of how disciplined execution and field-tested systems deliver lasting value in today’s industrial environment.

Proven Partner

Projects like this set a new standard for industrial construction in the United States. Want to learn more about how Hawk EPC’s engineering solutions can transform your operations?

Follow us on LinkedIn for more project updates and innovations in industrial construction.

0 Comments